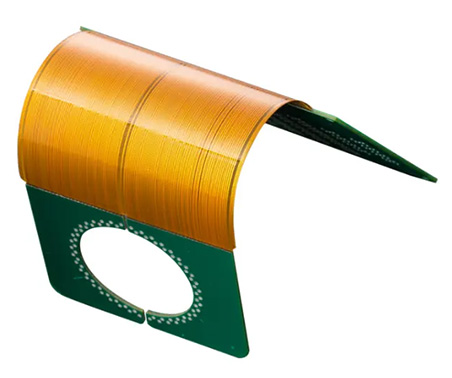

Flexible PCB

Name: Flexible PCB

Composition:insulating film; conductor; adhesive

Features:

✿ Short: The assembly time is short and all lines are configured. It saves the connection work of redundant cables.

✿ Small: The volume is smaller than that of PCB, which can effectively reduce the volume of the product and increase the convenience of carrying.

✿ Lightweight: lighter weight than PCB can reduce the weight of the final product

✿ Thin: Thinner than PCB

Process: plate making, parts installation, process design, welding, pressure sensitive contactor welding, painting, assembly and other processes

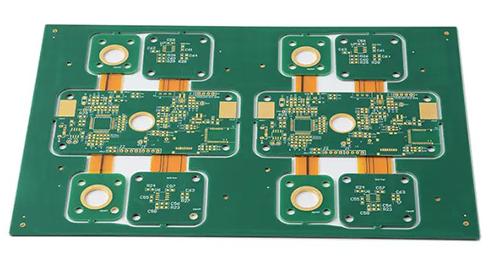

What is the difference between Flexible PCB and PCB

✿ Different forms: For PCB rigid circuit boards, unless the circuit is made into a three-dimensional form by filling film glue, the circuit board is generally flat. Therefore, the design of electronic products should make full use of the three-dimensional space, and the FPC flexible circuit board is a good solution. The current common space extension solution for PCB rigid circuit boards is to use slots and interface cards. FPC flexible circuit boards can be made with similar structures as long as they are designed through transfer, and the directional design is also more flexible.

✿ Different features: FPC generally uses PI as the base material, which can be bent and flexed arbitrarily. PCBs generally use FR4 as the base material, which cannot be bent or flexed.

✿ Different uses: FPC flexible circuit boards are used in links that require repeated deflection and some small parts, while PCB rigid circuit boards are often used in places that do not require bending and are relatively hard.

Applications: consumer electronics; industrial automation; medical electronics; automotive electronics

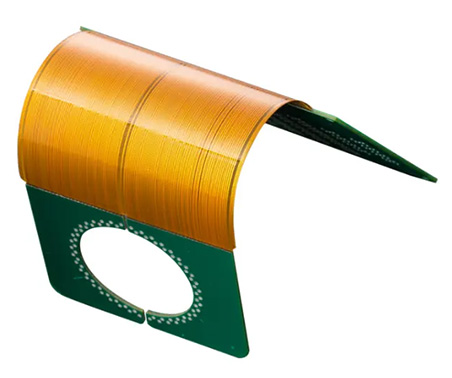

Composition:insulating film; conductor; adhesive

Features:

✿ Short: The assembly time is short and all lines are configured. It saves the connection work of redundant cables.

✿ Small: The volume is smaller than that of PCB, which can effectively reduce the volume of the product and increase the convenience of carrying.

✿ Lightweight: lighter weight than PCB can reduce the weight of the final product

✿ Thin: Thinner than PCB

Process: plate making, parts installation, process design, welding, pressure sensitive contactor welding, painting, assembly and other processes

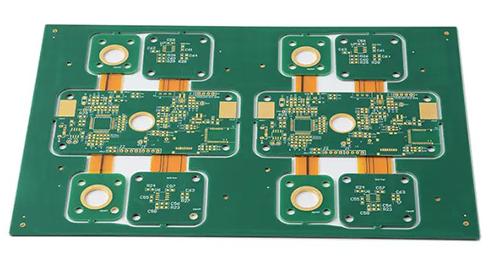

What is the difference between Flexible PCB and PCB

✿ Different forms: For PCB rigid circuit boards, unless the circuit is made into a three-dimensional form by filling film glue, the circuit board is generally flat. Therefore, the design of electronic products should make full use of the three-dimensional space, and the FPC flexible circuit board is a good solution. The current common space extension solution for PCB rigid circuit boards is to use slots and interface cards. FPC flexible circuit boards can be made with similar structures as long as they are designed through transfer, and the directional design is also more flexible.

✿ Different features: FPC generally uses PI as the base material, which can be bent and flexed arbitrarily. PCBs generally use FR4 as the base material, which cannot be bent or flexed.

✿ Different uses: FPC flexible circuit boards are used in links that require repeated deflection and some small parts, while PCB rigid circuit boards are often used in places that do not require bending and are relatively hard.

Applications: consumer electronics; industrial automation; medical electronics; automotive electronics

Total: 4

Page: 1 / 1

First

←Previous

Next→

End

Ultra PCB

Ultra PCB